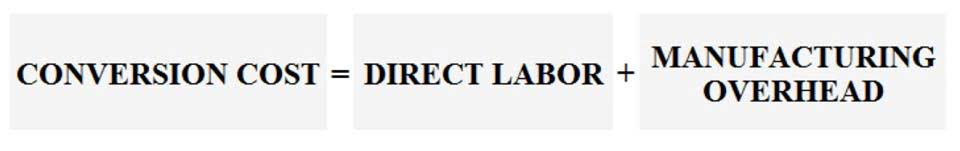

Calculating incremental manufacturing cost can be complex due to the dynamic nature of production environments and the need for accurate data. Allocating variable overhead costs, such as utilities or maintenance, often involves shared resources, requiring systematic approaches like activity-based costing. Non-linear cost behavior, such as economies or diseconomies of scale, further complicates calculations. Moreover, this cost can be influenced by external factors such as inflation or fluctuations in currency values.

Product Review: Parrot Anafi AI+

Incremental manufacturing cost refers to the additional expenses a company incurs when increasing production output. Unlike fixed costs, which remain constant regardless of production levels, recording transactions incremental costs fluctuate with changes in production volume. This concept is critical when businesses assess the financial viability of producing additional units. From a financial perspective, incremental cost analysis helps in evaluating the financial impact of a decision.

How to Calculate Incremental Cost?

- Unlike fixed costs, which remain constant regardless of the level of production, incremental costs vary with the level of output and can significantly impact the average cost per unit.

- Therefore, firms should undertake a thorough cost-benefit analysis to determine whether outsourcing presents an attractive financial proposition.

- Assuming variable costs of $4 per unit, the costs under the original revenue is $40,000 (10,000 x 4) and $48,000 under the alternative revenue scenario.

- For instance, if a manufacturing process uses a great deal of energy, then utility cost would be a variable cost.

The calculator is highly accurate and provides results rounded to two decimal places, making it suitable for most business and financial applications. Yes, the calculator is flexible and works for any scale of production, whether small or large, as long as you input accurate values. Imagine that you are the owner of a small business that manufactures and sells widgets.

Importance of Incremental Cost in Decision Making

It s critical to take into account all increments of cost when estimating whether it’s beneficial or not to expand your product line. It is crucial to note here that irrelevant costs should be avoided as they do not hold any relevance in decision-making processes, and considering them Bookkeeping for Consultants leads to wastage of resources. Incremental cost analysis empowers decision-makers to optimize their choices.

They are always composed of variable costs, which are the costs that fluctuate with production volume. Marketing strategists use incremental cost analysis to assess the viability of promotional campaigns. If the incremental cost of acquiring a customer through a new marketing channel is less than the lifetime value of that customer, the strategy is considered successful. Yes, the calculator works well for any product or service, but high variability in costs may require more detailed cost analysis beyond the incremental cost calculation. The marginal cost of capital is the additional cost a company incurs when it finances an additional project. Incremental costs can be positive or negative, depending on the direction of the change, while marginal costs are usually positive, as more output requires more inputs.

- Sunk costs refer to expenses that have already been incurred and cannot be recovered.

- By analyzing these incremental costs, the firm can allocate its resources effectively and maximize returns.

- By considering different perspectives, utilizing a structured approach, and incorporating examples, individuals can make informed decisions when analyzing alternative courses of action.

- By considering various perspectives and utilizing tools like cost-benefit analysis, decision-makers can make informed choices that align with their goals and optimize resource allocation.

- Moreover, incremental cost analysis provides valuable insights from different viewpoints.

- For any business decision that involves changing volumes or adding products/services, incremental costs are vital for determining the financial impact.

It involves analyzing the additional expenses incurred by a company when producing one more unit of a product or providing an additional service. By understanding incremental costs, startups can make informed decisions regarding pricing, production levels, and resource allocation. Understanding the concept of incremental manufacturing cost is essential for businesses aiming to optimize production efficiency and profitability. This financial metric helps companies determine the additional costs incurred when increasing production levels, providing insights into operational decision-making.

Evaluate the financial impact:

- Several factors influence marginal cost, and examining these elements can provide valuable insights into the dynamics of production costs.

- Managers can consider analyzing past financial reports, direct labor and overhead expenses, among other areas covered over time in performing this task.

- If the long-run predicted cost of the raw materials is expected to rise, then electric vehicle prices will likely be higher in the future.

- Remember, identifying relevant costs requires a holistic approach, considering both short-term and long-term implications.

- This is because fixed costs are not relevant to the decision of whether or not to pursue a new project or venture.

- Remember, incremental cost isn’t just about numbers; it’s about informed choices.

To calculate the incremental cost, you must first determine the total cost of the two different options or incremental cost choices. Subtract the total cost of the first option from the second option to determine the incremental cost. These costs may include but are not limited to the purchase, transportation, installation, and maintenance of the equipment. It is important for businesses to carefully calculate these costs before investing in new equipment to ensure that it is a viable financial decision.